Parts Cleaning Waste Heat Recovery

BMR Thermal Inc. Supplies Waste Heat Recovery Equipment For Electric Savings in Part Cleaning Application.

In many part machining applications parts are required to be cleaned and dried to remove lubricating fluids and other possible contaminants and particulate from the machining process. Many steel parts as well as some glass parts go through a wash and dry prior to final assembly, marking and/or packaging.

The washing equipment typically uses hot water to break down and remove the solvents and oils from the part surfaces with water required to be at 140F or higher.

The Condex waste heat recovery system is ideal for supplying the necessary hot water and can be used as a preheat or as a complete replacement for gas fired or electric water heaters typically used in smaller part cleaning applications.

One application on the Massachusetts North Shore includes a Casso Solar infrared dryer after the parts washer. The 210F hot exhaust from the dryer is directed through a Condex waste heat recovery system to generate 140F hot water.

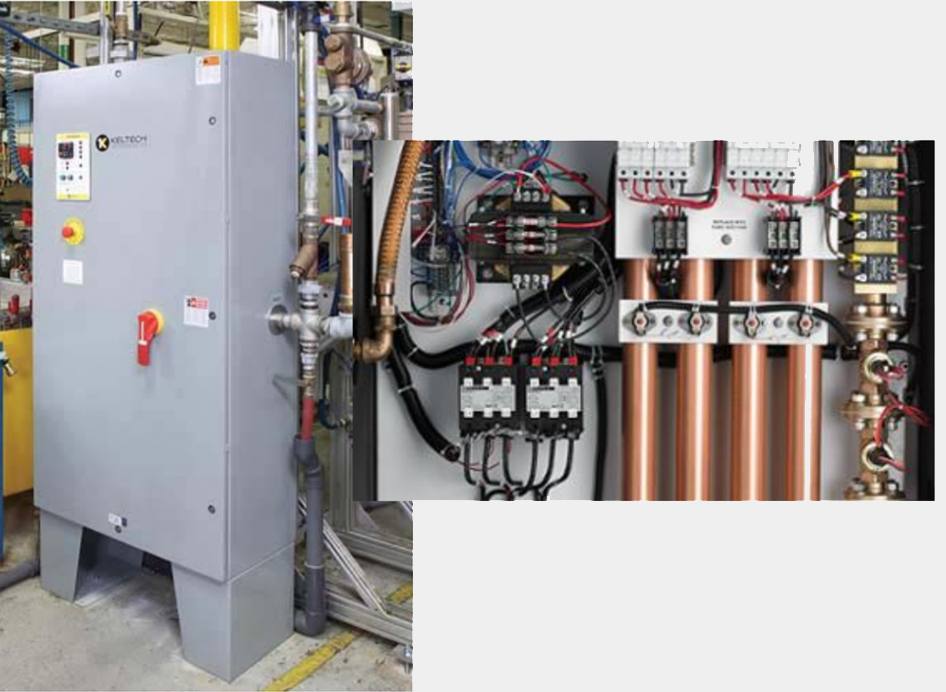

Hot water from the Condex is connected to the supply piping of the customers Keltech electric hot water heater, drastically reducing the electricity used by the plant for hot water heating.

This solution could be applied to many parts washing applications including bottle washing for beverage bottling facilities and breweries, steel part machining and glass machining processes.

Utility incentives may be available for thermal as well as electricity savings.