CECO CCA

CCA's core expertise is emissions technologies for gaseous, liquids and solid fuels, including combustion and post combustion NOx controls. CCA offers burners and burner upgrades for coal, oil, and gas-fired systems, new burners, overfire air (OFA), flue gas recirculation (FGR), targeted water tempering, SNCR, and SCR. Technologies can be implemented alone or in combination to achieve high levels of NOx control.

LOW NOX BURNERS

Our CCA brand low-NOx burners (LNB) are configured to stabilize the combustion process and allow the unit to be operated at lower excess O2 by utilizing a flame stabilizer. To enhance the NOx reduction capabilities, the flame stabilizer is designed with internal air/fuel staging. This sets up fuel-rich and lean zones downstream of the stabilizer in the primary combustion zone where the majority of the NOx emissions are formed, providing additional staging, flame stability and lower NOx emissions.

Burner Modifications

CCA can offer burner modifications for existing burners by any manufacturer to add natural gas firing, change from heavy to light or bio based fuel oil and general optimization for efficiency and emissions. Specifically designed gas burner elements and complete liquid fuel atomizers are offered for stable flames that fit the furnace. Modeling of the existing air system and windbox is offered to assure burner performance.

SELECTIVE NON-CATALYTIC REDUCTION (SNCR)

Our CCA brand Selective Non-Catalytic Reduction (SNCR) systems provide a low cost technique to reduce NOx emissions by 30%-60% for both boilers and lime kilns. The SNCR process involves injecting a reagent into the flue gas in the appropriate temperature window. The reagent reacts with NOx to form harmless nitrogen and water. The design, arrangement, and location of the reagent injectors are critical to the performance of the SNCR system. Our advanced technology utilizes variable droplet size control and automatic titling based on furnace temperature, to enhance the NOx reduction performance.

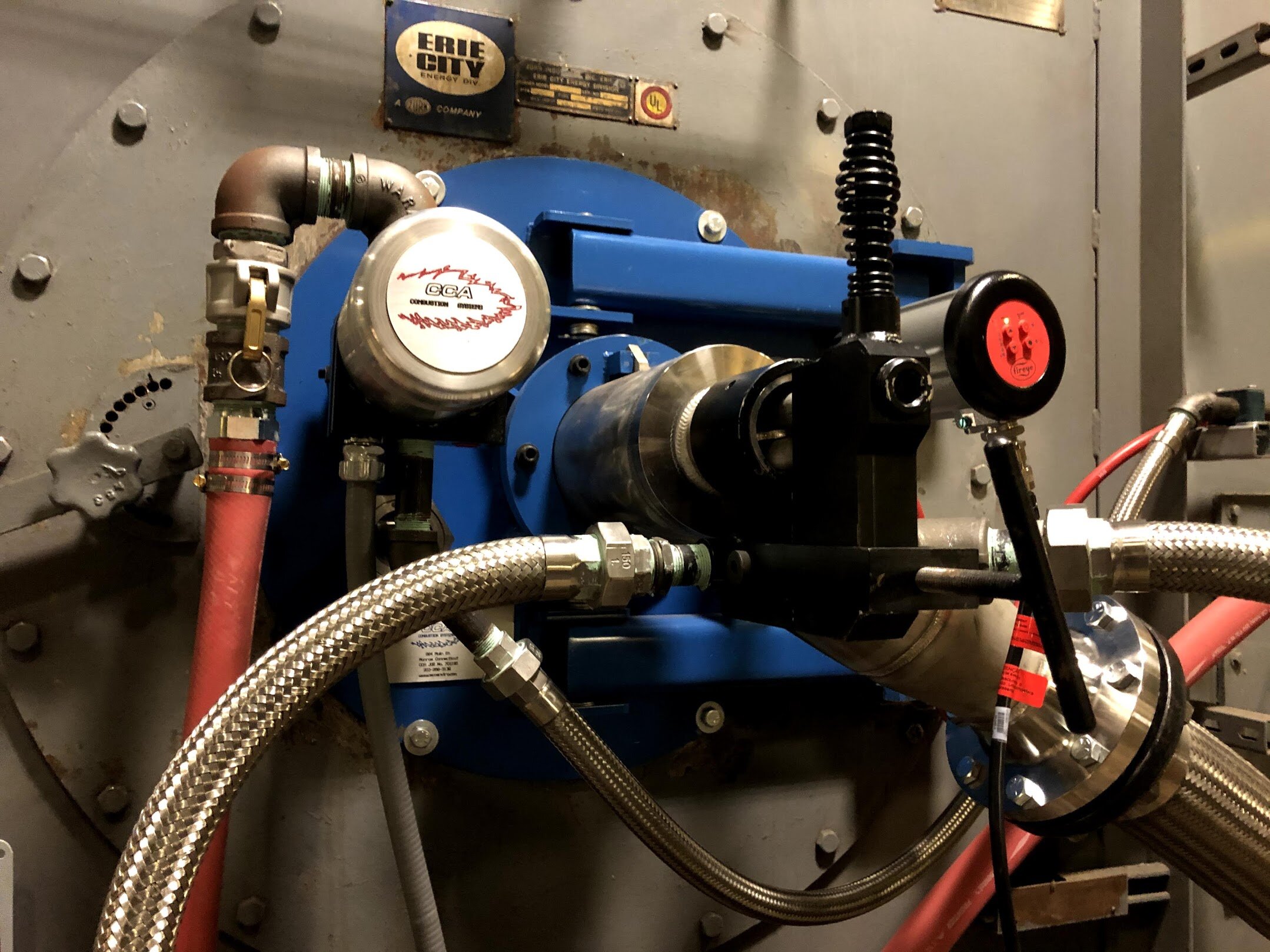

Fuel Trains

With any new burner or burner retrofit, new fuel and atomizing trains are available to meet local area classification and NFPA requirements.

FLUE GAS RECIRCULATION (FGR)

Flue Gas Recirculation (FGR) is a powerful nitrogen oxide (NOx) control technique that significantly reduces NOx emissions by recirculating flue gases from the boiler exhaust duct into the main combustion chamber. This process reduces peak flame temperature and lowers the percentage of oxygen in the combustion air/flue gas mixture, thereby reducing thermal NOx formation.

SCR Systems

uREA AND AMMONIA BASED SYSTEMS

DIRECT INJECTION and VAPORIZER STYLE SYSTEMS.

Our CCA brand SCR Systems automatically inject a urea or ammonia based reagent into the exhaust gas of fuel oil or natural gas boilers, furnaces, or turbines to reduce NOx emissions. Each system is engineered to optimize efficiency, performance and reliability, while meeting stringent environmental standards.

The Direct Injection System eliminates the need for heaters and blowers associated with traditional SCR vaporizer type systems.

Urea based SCR systems are a safe alternative to storing hazardous ammonia on site.